Non-contact sensors detect or measure an object’s physical characteristics without having direct contact with the object. They measure physical attributes, including thickness, closeness, displacement, or distance. Non-contact displacement sensors use technologies such as capacitance, fiber optic, or laser triangulation to collect readings by emitting energy. Non-contact sensors are quicker, particularly for applications requiring high sampling rates, and won’t slow down a target’s motion. Additionally, they may measure multiple places without applying pressure to the measured object. The ideal option for measuring silicon wafers is a non contact temperature sensor, which is also utilised in many industrial applications.

Let’s discuss non-contact temperature measurement:

Non contact temperature measurement

The non-contact temperature sensor is used for measuring a body’s temperature using infrared rays that the body emits. It is a favored strategy for dynamic operations that need a quick response and small, moving, or inaccessible objects. Selecting the appropriate noncontact temperature measuring equipment for a given application can be made easier by being aware of the fundamentals of temperature measurement technology, its characteristics, and its many features.

A non-contact thermometer measures an object’s surface temperature by detecting the infrared light it emits. The infrared region of the electromagnetic spectrum is located outside the range of human vision. Wavelengths in the infrared range from 0.75 m to 1000 m.

Temperature is crucial in many different industries, including manufacturing, quality control, the medical sector, etc. Productivity is increased, and product quality is enhanced by precise temperature monitoring. Infrared technology has been successfully applied in industrial and scientific contexts for many years.

However, recent technological advancements have cut expenses and attracted a large user base and applications. Noncontact IR thermometry’s key benefits are its quickness, lack of noise, and capacity to measure temperatures up to 3000°C.It is also possible to utilize infrared thermometers on moving and inaccessible items. However, surface temperatures are the only ones that can be measured with infrared equipment.

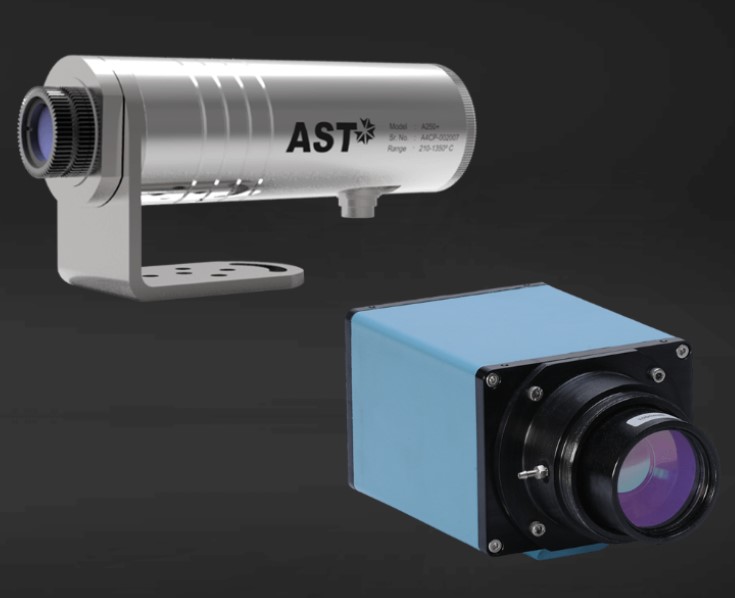

Every form of matter emits infrared radiation depending on its temperature when it is above absolute zero. An object’s temperature is determined by how vigorously its molecules move. The temperature of the target’s surface can be determined from the infrared radiation that the target emits. These infrared radiations are collected, and the temperature is determined using pyrometers or infrared thermometers.

Today’s market offers various pyrometers, depending on the varied applications. Temperature is measured using a two-color pyrometer, also known as a ratio pyrometer, which uses two distinct wavelengths. The primary benefit of non contact temperature sensor measurement is that emissivity is independent, therefore, changes in emissivity have no impact on the temperature reading.

Points to consider while selecting an infrared pyrometer

Check for dust, dirt, and humidity

Non-contact temperature sensors rely on the capacity to view the object you want to measure. The sensor’s capacity to measure accurately is impaired if there is dirt, debris, or fog on the sensor’s lens, leading to incorrect information. This may typically be avoided by attaching an air purge collar to the sensing head.

Smoke, steam, and dust may be present in the surroundings in some plastics applications, which can again make it difficult to acquire an exact measurement.

How will you aim for the infrared sensor?

Since the pieces are large enough to make missing them nearly difficult, aiming the non-contact temperature sensor in many applications is simple. However, targeting is crucial when taking into account tiny elements and when taking measurements through machine gaps.

The quickest and most widely utilized technique is laser aiming. The Optris dual laser aiming system clearly displays both the location and size of the measuring spot.

Size of the thing you are measuring

The size of the object to be measured must be known when choosing an infrared pyrometer in order to choose the right sensor. On the component, the non-contact temperature sensor’s measurement point must be completely positioned. There was a wide range of options when it comes to choosing a sensor, including spot sizes as small as less than 1mm in some circumstances.

Infrared pyrometer output signal

In order for your sensor to work with your instrumentation, you will need to know what signal it needs. Fortunately, sensors offer a wide range of configuration options, many of which can be done directly on the sensor.

Speed of response

By definition, infrared temperature sensors respond far more quickly than contact probes like thermocouples or RTDs. Though in some applications the ability to respond quickly is crucial. A sensor will often respond in less than 100 milliseconds.

Bottom line

Finally, the above-mentioned are about the non-contact temperature measurement. The non-contact temperature sensor is the best choice to measure a particular thing because it takes accurate measurements without having physical contact.

Also read: What to look for selecting temperature transmitter

| Homepage | Click Hear |